PE PP pelletizer muchina mutengo

Tsanangudzo

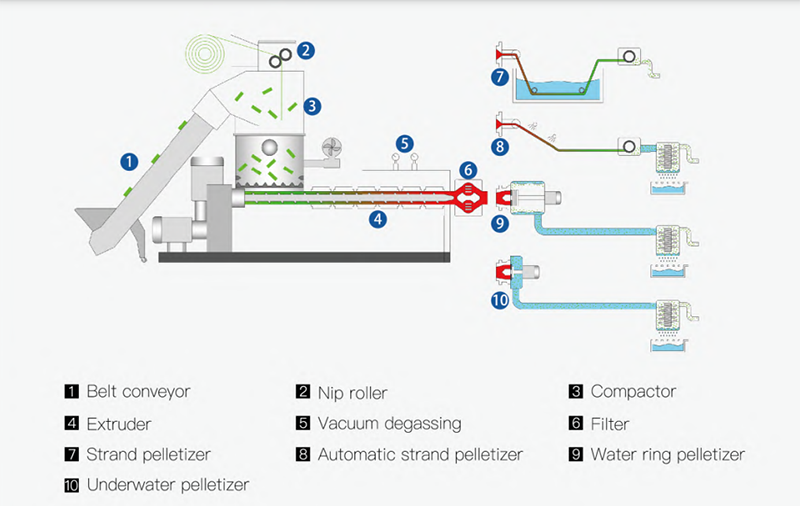

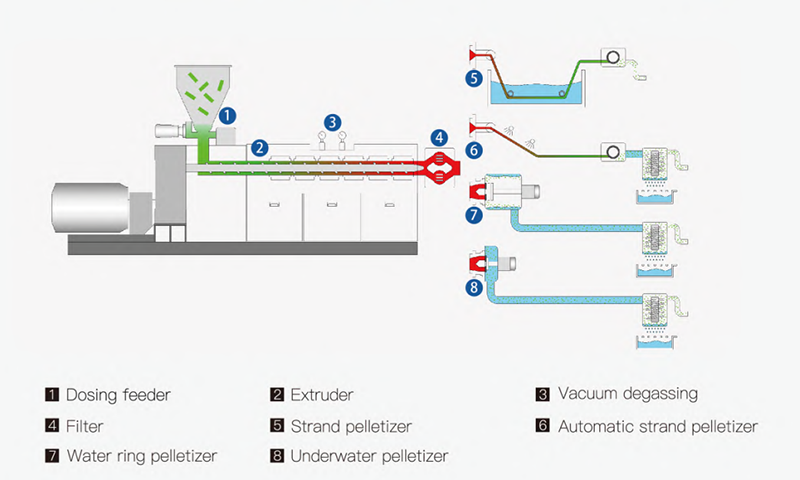

Plastic pelletizer muchina ndiyo maitiro ekushandura mapurasitiki kuita magranules. Mukushanda, iyo polymer melt yakakamurwa kuita mhete yetambo inoyerera nemu annular kufa ichipinda mukamuri yekucheka yakafashama nemvura inogadziriswa. Musoro wekucheka unotenderera murukova rwemvura unocheka tambo dzepolymer kuita mapellets, ayo anobva aburitswa kubva mukamuri yekucheka.

Plastic pelletizing chirimwa chinogona kugadziridzwa sechisina (muchina mumwe chete weextrusion) uye kaviri nhanho kurongeka (mumwe mukuru extrusion muchina uye imwe diki yechipiri extrusion muchina).

"Hot Cheka" mvura-mhete kufa kumeso pelletizing uye "Cold Cheka" strand pelletizing nzira dziripo zvichienderana nezvaunoda.

Melt pelletizing (hot cut): Nyunguduka ichibva mudhishi inochekwa pakarepo kuita mapellets anofambiswa nekutonhodzwa nemvura kana gasi;

Strand pelletizing (inotonhora yakachekwa): Melt ichibva mumusoro wekufa inoshandurwa kuita tambo dzinodimburwa kuita pellets mushure mekutonhodza uye kusimba.

Isu tinokwanisa kugadzira yakanaka pelletizer muchina wako uine yakanaka pelletizer muchina mutengo.

Details

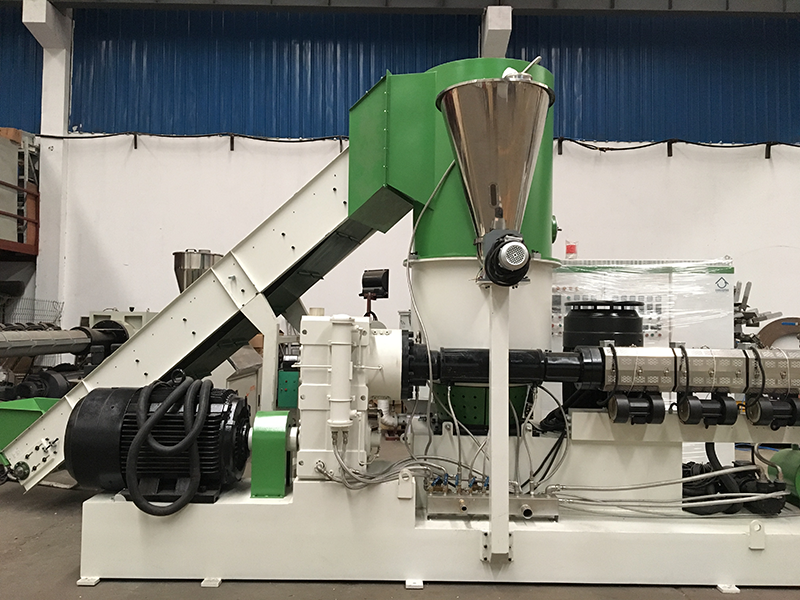

Compactor Unit

Iko kusanganiswa kweakakwira ekumhanya anotenderera blades uye akamira mablades anomhanyisa kumhanya kwekukochekera uye kutungamira zvinhu mune extruder screws.

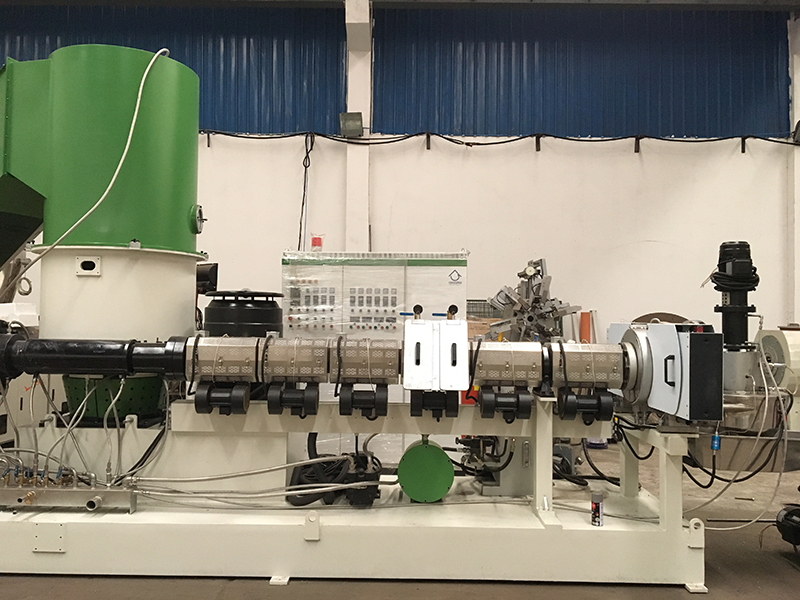

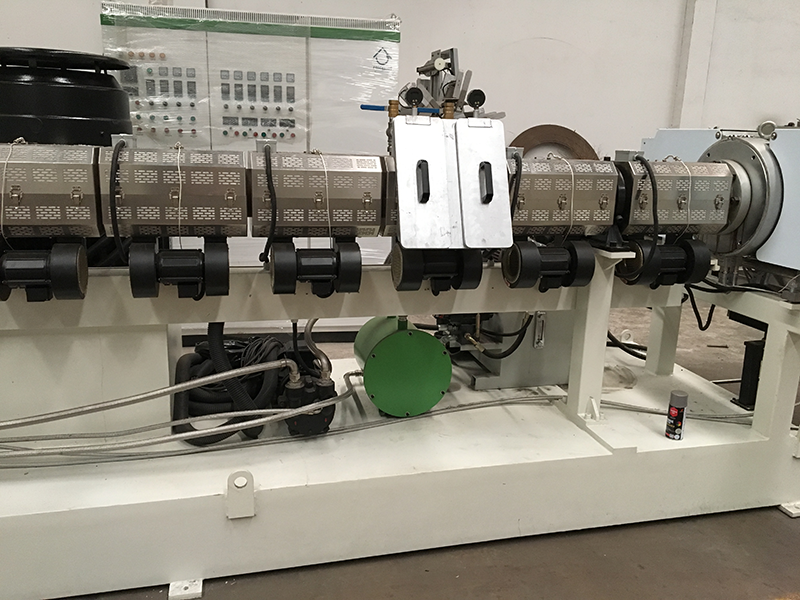

Extruder Unit

A specialized single screw extruder inoshandiswa kunyungudutsa zvinyoro nyoro iyo pre-yakaumbwa zvinhu.

Zvimedu zvepurasitiki zvichanyungudutswa zvakanaka, plastiki mu extruder.

Yakakwirira inoshanda dhiramu uye screw inoshandiswa extruder ine yakanakisa plasticizing mhedzisiro uye yakakwirira kubuda huwandu, tora yakakwira kupfeka inodzivirira alloy zvinhu kuti ive nechokwadi 1.5 nguva yehupenyu hwesevhisi yeyakajairika.

Degassing unit

Iine kaviri-zone vacuum degassing system, yakawanda inoputika inogona kubviswa zvinobudirira, kunyanya inorema yakadhindwa firimu uye zvinhu zvine zvimwe zvemvura.

Sefa

Plate type, pistion type uye otomatiki yekuzvichenesa mhando sefa, Yakasiyana sarudzo zvinoenderana nekusachena kuri mukati mezvinhu uye tsika yemutengi.

Plate type sefa inodhura-inoshanda uye iri nyore kushandisa iyo inonyanya kushandiswa kune yakajairwa thermoplastic semazuva ese

filtration solution.

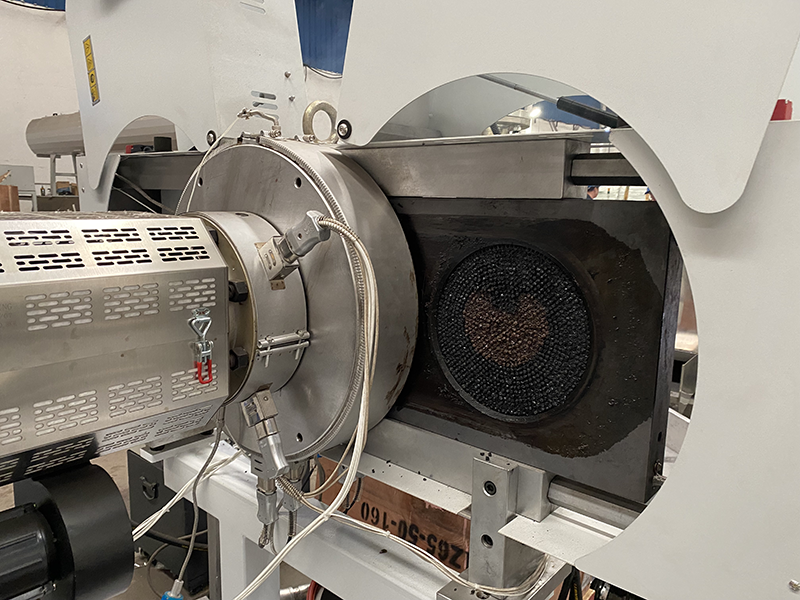

Mvura mhete pelletizer

Kucheka kumhanya kwepelletizer inodzorwa otomatiki nePLC zvichienderana nekudzvanywa kwemusoro wekufa, iyo inogona kuwana saizi yeyunifomu yekubuda pellets.

Mablades epelletizer anobata kuti afe ndiro otomatiki nepneumatic system, ita shuwa mablades

kubata neplate yekufa zvakanaka, iri nyore kushanda uye kudziviswa kubvongodzwa.

Technical Data

| Type | KCP80 | KCP100 | KCP120 | KCP140 | KCP160 | KCP180 | |

| Kugona (kg/h) | 150-250 | 300-420 | 400-600 | 600-750 | 800-950 | 1000-1200 | |

| Kushandiswa kwesimba (kWh/kg) | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | |

| Compactor | Vhoriyamu(L) | 300 | 500 | 800 | 1000 | 1200 | 1400 |

| Motokari Simba(kw) | 37-45 | 55-75 | 75-90 | 90-132 | 132-160 | 160-185 | |

| Extruder | Siruvha Diameter(mm) | φ80 | φ100 | φ120 | φ140 | φ160 | φ180 |

| L/D | 30-40 | 30-40 | 30-40 | 30-40 | 30-40 | 30-40 | |

| Motokari magetsi (kw) | 55-75 | 90-110 | 132-160 | 160-200 | 250-315 | 315-355 | |

| Sefa(sarudzo) | Two position plate type | ● | ● | ● | ● | ● | ● |

| Mbiri yepiston mhando | ○ | ○ | ○ | ○ | ○ | ○ | |

| Back flush piston type | ○ | ○ | ○ | ○ | ○ | ○ | |

| Otomatiki selfcleaning mhando | ○ | ○ | ○ | ○ | ○ | ○ | |

| 2nd Extruder (kusarudza) | Siruvha Diameter(mm) | φ100 | φ120 | φ150 | φ150 | φ180 | φ200 |

| L/D | 10-18 | 10-18 | 10-18 | 10-18 | 10-18 | 10-18 | |

| Motokari magetsi (kw) | 37-45 | 45-55 | 55-75 | 75-90 | 90-110 | 110-160 | |

| Kudzika (sarudzo) | Mvura mhete pelletizer | ● | ● | ● | ● | ● | ● |

| Strand pelletizer | ○ | ○ | ○ | ○ | ○ | ○ | |

| Automatic strand pelletizer | ○ | ○ | ○ | ○ | ○ | ○ | |

| Underwater pelletizer | ○ | ○ | ○ | ○ | ○ | ○ | |

● mwero ○ imwe nzira