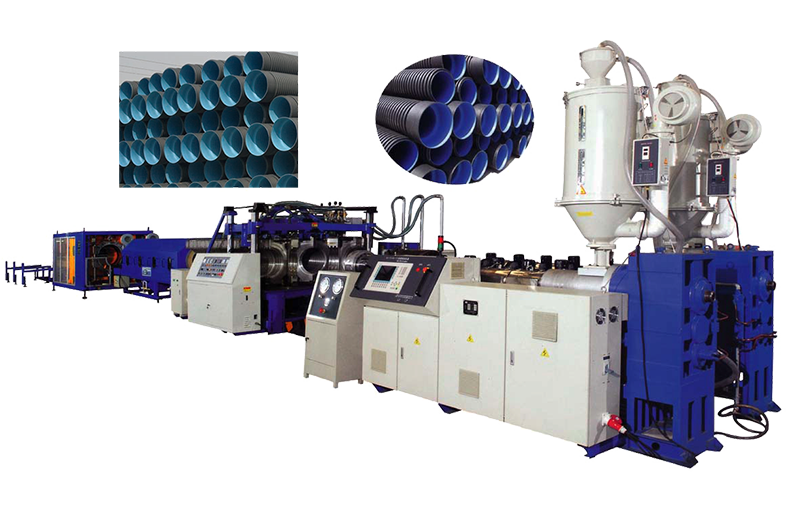

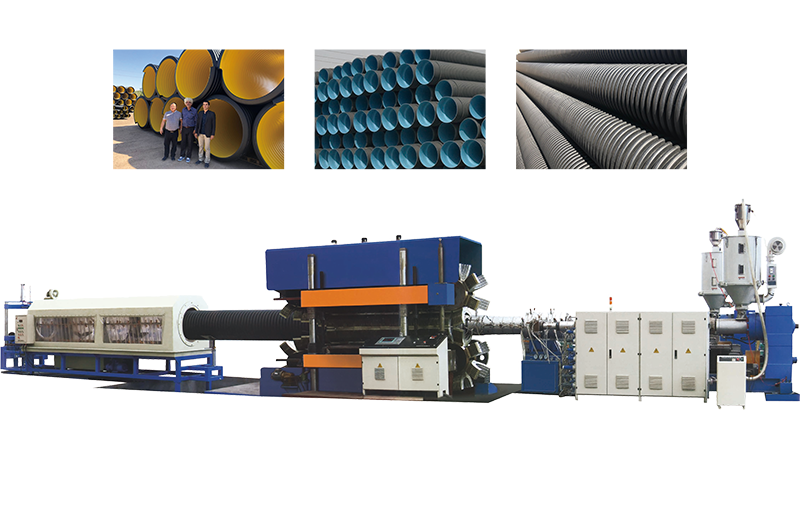

High Speed PE PP (PVC) Corrugated Pipe Extrusion Line

Tsanangudzo

Plastic corrugated pombi muchina unoshandiswa kugadzira mapaipi epurasitiki ane marata, ayo anonyanya kushandiswa mumaguta emvura, masisitimu etsvina, mapurojekiti emigwagwa mikuru, mapurojekiti ekudiridza ekuchengetedza mvura mumapurazi, uye anogona kushandiswawo mumapurojekiti ekufambisa emakemikari emugodhi, aine huwandu hwakawanda hwekushandisa. Corrugated pombi kugadzira muchina une zvakanakira zvekubuda kwepamusoro, yakagadzikana extrusion uye yakakwirira degree re automation. Iyo extruder inogona kugadzirwa zvinoenderana neakakosha mamiriro ezvinhu emushandisi, senge PE PP kana PVC. PE PP kaviri-madziro corrugated pombi extrusion mutsara shandisa mhando nyowani yepamusoro-inoshanda single/twin screw extruder. PVC corrugated pombi muchina shandisa hombe sandara mapatya kana conical mapatya extruder. Ne single layer uye maviri akaturikidzana esarudzo. Kugadzira mapaipi maviri emadziro emarara, kune marudzi maviri,horizontal kaviri rusvingo marata pombi extrusion mutsetseuyevertical double wall corrugated pipe extrusion line.

Process Flow

Raw material → Kusanganisa → Vacuum Feeder → Plastic Hopper Drier →Extruder →Extrusion Mold →Kugadzira Mold → Mvura inotonhodza Kugadzira muchina →Pfaya Mvura Inotonhorera →mushini wekucheka →Stacker

Zvinhu uye Zvakanakira

1. HDPE inotora rudzi rutsva rwepamusoro-soro imwe / twin screw extruder, uye PVC inotora yakakura flat twin kana conical twin extruder. Big conical twin-screw extruder kana parallel twin-screw extruder inogona kuona yakanakisa plasticization pane yakaderera tembiricha uye yakagadzikana extrusion.

2. Iyo module yekutonhora nzira inomanikidzwa kutonhora kwemvura, iyo inovandudza zvakanyanya kutonhora kumhanya kwemodule, kuitira kuti iwane yakakwirira-yekukurumidza kugadzirwa.

3. Iyo corrugated pombi mutsara inonziwo kaviri madziro corrugated pombi muchina mutsetse unogona kuona pa-line flaring kuti ive nechokwadi chekuti zvakasiyana-siyana zvepombi yakaumbwa zvinosangana nezviyero.

4. Inotengeswa kunze kwechiyero-inogadzirisa vharafu inogadzirisa kuumba kudzvinyirira kugadzikana uye yakavimbika.

5. Horizontal type corrugator

6. Kushanda plateform inogadziriswa katatu-dimensionally.

7. Automatic protection system inotanga uye inoshanda inodzoka kana simba rapera.

8. Automatic lubrication station

9. Mold blocks akagadzirwa neakakosha aruminiyamu alloy uye anoratidza huremu huremu, simba rakakwirira, kunaka kusagadzika, diki-inoshanda yekuwedzera kwekupisa.

10. Kutonhodza mhepo uye kutonhodza mvura kuitira kutonhodza zviumbwa zvine makota zvinogadzira pombi nokukurumidza.

11. Iyo corrugated pipe yekucheka muchina ine zvakanakira yakakwirira chaiyo uye isina guruva.

12. Mutsara wakakwana unotora PLC micro-computer control system iyo inogona kuoneka inoratidza kunyunguduka kwekushisa uye kumanikidzwa, kuumba kukurumidza, kukanganisa alarm uye inewo kuchengetedza kukwanisa kwemaitiro ekutanga.

Details

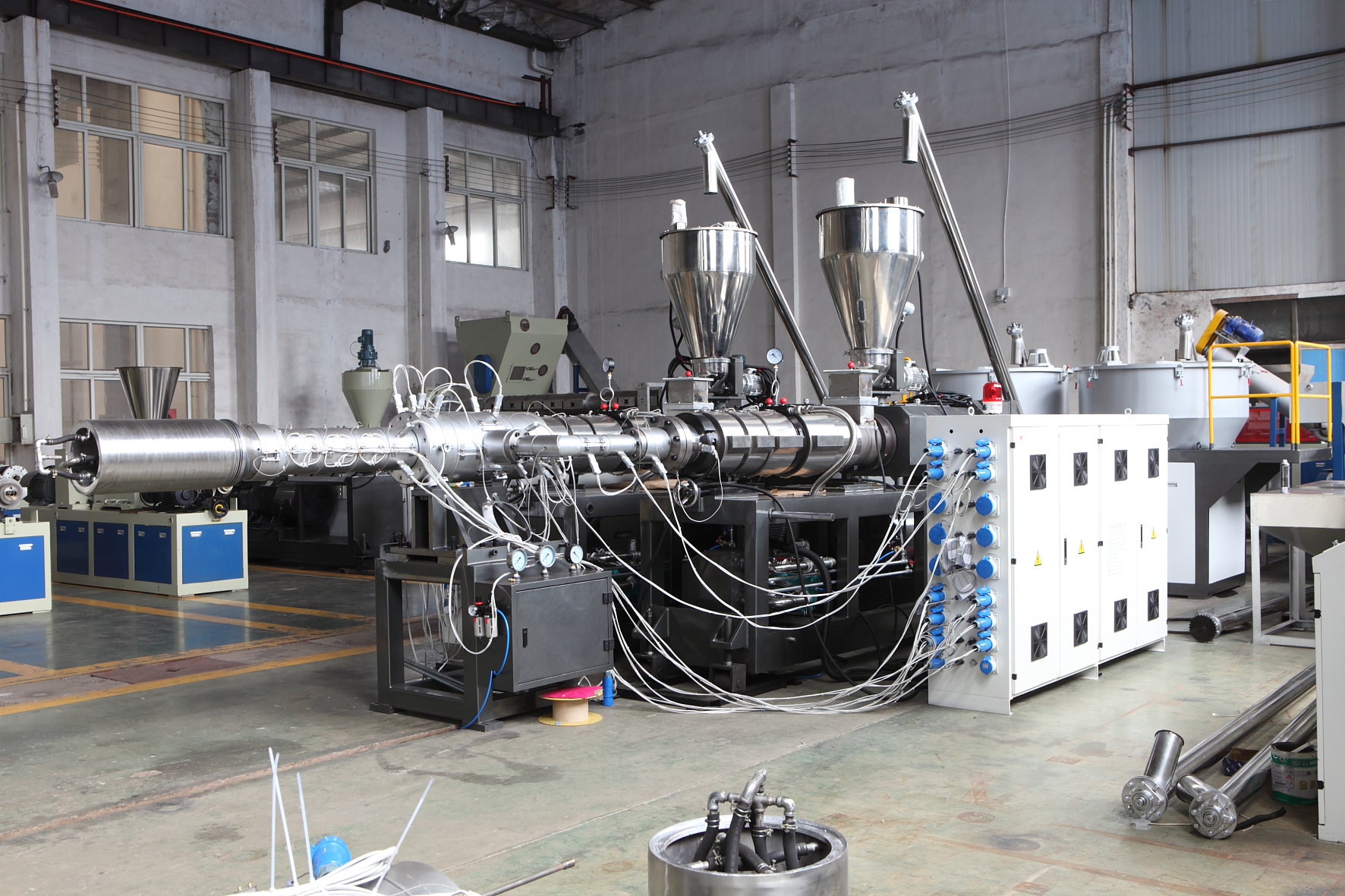

Single Screw Extruder yePE/PP

Zvichienderana ne33: 1 L/D reshiyo yekugadzira screw, isu takagadzira 38:1 L/D reshiyo. Kuenzaniswa ne33: 1 reshiyo, 38: 1 chiyero ine mukana we100% plasticization, wedzera kubuda kwehuwandu ne30%, kuderedza kushandiswa kwemagetsi kusvika ku30% uye kusvika kunenge mutsara extrusion performance. Adopt L/D reshiyo 38:1 sikuruu yemidziyo yemhandara uye L/D 33:1 sikuruu yezvishandiso zvakare.

Simens Bata Screen uye PLC

Nyorera chirongwa chakagadziridzwa nekambani yedu, iva neChirungu kana mimwe mitauro kuti uise muhurongwa.

Spiral Chimiro cheBharel

Kudyisa chikamu chedhiramu shandisa spiral chimiro, kuve nechokwadi chekudya chenyama chakagadzikana uye zvakare kuwedzera simba rekudyisa.

Special Design of Screw

Screw yakagadzirwa neyakakosha chimiro, kuve nechokwadi chepurasitiki yakanaka uye kusanganisa. Zvinhu zvisina kunyungudutswa hazvigone kupfuura ichi chikamu che screw.

Mhepo Yakatonhodzwa Ceramic Heater

Ceramic heater inovimbisa hupenyu hurefu hwekushanda. Iyi dhizaini ndeyekuwedzera nzvimbo iyo hita inosangana nemhepo. Kuve nemhepo inotonhorera inotonhorera.

High Quality Gearbox

Kurongeka kwegiya kuve nechokwadi 5-6 giredhi uye yakaderera ruzha pazasi 75dB. Compact chimiro asi ine yakakwirira torque.

Conical Twin Screw Extruder yePVC

Ose ari maviri conical twin screw extruder uye parallel twin screw extruder anogona kuiswa kugadzira PVC. Ne tekinoroji yazvino, kudzikisa simba uye kuve nechokwadi chekugona. Zvinoenderana neyakasiyana mafomula, isu tinopa akasiyana screw dhizaini kuti ive nechokwadi cheplasticizing mhedzisiro uye yakakwirira huwandu.

Extrusion Mold

Ese ari maviri ekunze layer uye yemukati layer anoburitswa mukati memusoro wekufa. Imwe neimwe nzira inoyerera mukati memusoro wekufa inoiswa zvakaenzana. Imwe neimwe chiteshi mushure mekupisa kupisa uye girazi polishing kuti ive nechokwadi chekuyerera zvakanaka. Zvakare kufa musoro kunopa mweya wakamanikidzwa pakati pezviviri. Calibration sleeve inoshandiswa kutonhorera yemukati layer kuti iite pombi yakatsetseka uye yakati sandara mukati. Dzvinyiriro yemvura inoyerera mukati memaoko ekugadzirisa kuti ive yakanaka yekutonhodza. Vacuum inogadzirwa pane calibration sleeve pamusoro paunenge uchigadzira hombe dhayamita pombi, simbisa yemukati pombi kutenderera.

Kugadzira Mold

CNC machining inova nechokwadi chekuyera zviyero. A vacuum air duct uye mvura-inotonhorera chiteshi ine yakakura kuyerera muchinjiko-chikamu inovimbisa yakagadzikana, yepamusoro-soro, uye inoshanda kugadzirwa kwekushanda. Iyo module zvinhu ndeye yakakwirira-simba aluminium alloy, ine yakakwira yekupisa conductivity, yakanyanya kuoma, uye yakakwirira kupfeka kuramba. Chimiro chemodule chinotora yakabatanidzwa yekukanda maitiro ekukanda, ine denser mameseji uye yakakwira kugadzikana kwemafuta. Iyo yemukati yekurapa pamusoro peiyo module inovandudza kusimba uye kuoma kweiyo module, iyo inonyanya kuenderana neyakakwana kuumbwa kwema ripples. Iyo mold inotora CNC machining kuti ive nechokwadi chekurongeka kwayo uye kushanda zvakanaka.

Mvura inotonhorera Kugadzira muchina

Mvura inotonhora yekugadzira muchina unoshandiswa kuisa uye kufambisa corrugated mold, vacuum inogadzirwa kuti itore rekunze dhizaini mumarara mold kuti igadzire corrugated shape. Nekufambisa makora mold, pombi inodhonzwawo kubva pacorrugator.

Automatic Lubrication System

Otomatiki zora magiya kuita kuti marara mold ifambe zvakanaka.

Transmission Gear Rack

Gear rack inoiswa pamusoro pemarata mold. Ese magiya racks ari mushure me nitriding uye kupisa kurapwa, kupfeka kwenguva refu kuramba.

Upper Adjustment System

Nemagetsi gadzirisa furemu yepamusoro yehukuru hwakasiyana hwemarata. Nembiru ina, iva nechokwadi chekugadzirisa uye kwakarurama kugadzirisa.

Tension Kugadzirisa System

Kugadzirisa kusimba kwe mold kufamba, ita kuti mold ifambe zvakanaka.

Proportional Valve

Kudzora mweya wakagadzikana uye wakarurama, kugadzira pombi yakanaka uye socket chimiro.

Mold Cooling System

Nezvese zviri zviviri kutonhora kwemvura uye kutonhora kwemhepo, kuve nekutonhodza zvirinani, yakanaka uye inokurumidza kuumba pombi.

UPS Backup Power

Kana simba rakundikana, UPS backup simba simba rinopa simba kune corrugator kuti ibvise pombi kubva pane calibration sleeve. Kuti udzivise pombi yakanamira pane inogadzirisa sleeve mushure mekutonhora kwepombi uye kupera.

Pfayira Tangi Yemvura Inotonhorera

Kutonhodza tangi rinoshandiswa kutonhora pombi mberi.

Kubatsira Haul-off

Nekubatsira kudhonza kubva mudziyo, zvakare traction mudziyo unochinjika. Kukwevera pombi mberi.

Quality Spray Nozzle

Yemhando yekupfapfaidza nozzles ine zvirinani kutonhora mhedzisiro uye isiri nyore kuvharika netsvina.

Mvura Tangi Sefa

Nesefa mutangi remvura, kudzivirira chero tsvina yakakura kana mvura yekunze ichipinda.

Corrugated pipe yekucheka muchina

Iyo corrugated pombi yekucheka muchina ndeyepamusoro chaiyo uye haina guruva.

Aluminium Clamping Chishandiso

Isa aluminium clamping mudziyo kune akasiyana pombi saizi. Saizi yega yega ine yayo clamping mudziyo, hapana chikonzero chekuchinja chepakati kureba kana kune akasiyana pombi saizi.

Synchronization system

Yekucheka chiteshi inofambiswa nemota uye inverter. Panguva yekucheka, chiteshi chekucheka chiri kufamba chakafanana ne corrugator kudzivirira deformation yepombi.

Kucheka Banga Kaviri

Nemapanga maviri ekucheka pamwe chete, kuti ave nechokwadi chekuti chikamu chesoketi chagurwa zvakazara.

Stacker

Kutsigira nekuburutsa mapaipi. Hurefu hwe stacker hunogona kugadzirwa.

Kutsigira nekuburutsa mapaipi. Hurefu hwe stacker hunogona kugadzirwa.

Kuti tifambise marara pombi zvakanaka pane stacker, tinoshandisa simbi isina tsvina pamusoro pe stacker.

Kukoira pombi kuita roller, zviri nyore kuchengetedza uye kutakura. Inowanzoshandiswa pombi pazasi saizi 110mm. Iva nechiteshi chimwe chete uye kaviri chiteshi chesarudzo.

Technical Data

| Model | Saizi yepombi(mm) | Extruder | Kubuda (kg/h) | Kumhanya (m/min) | Total power(KW) | Mold (vaviri) | Kutonhodza system |

| SGB250 | 90-250 | SJ65 SJ75 | 300 | 1-4 | 150 | 48 | Kutonhora kwemhepo uye kutonhora kwemvura |

| SGB500 | 200-500 | SJ75 SJ90 | 600 | 1-4 | 200 | 40 | Kutonhora kwemhepo uye kutonhora kwemvura |