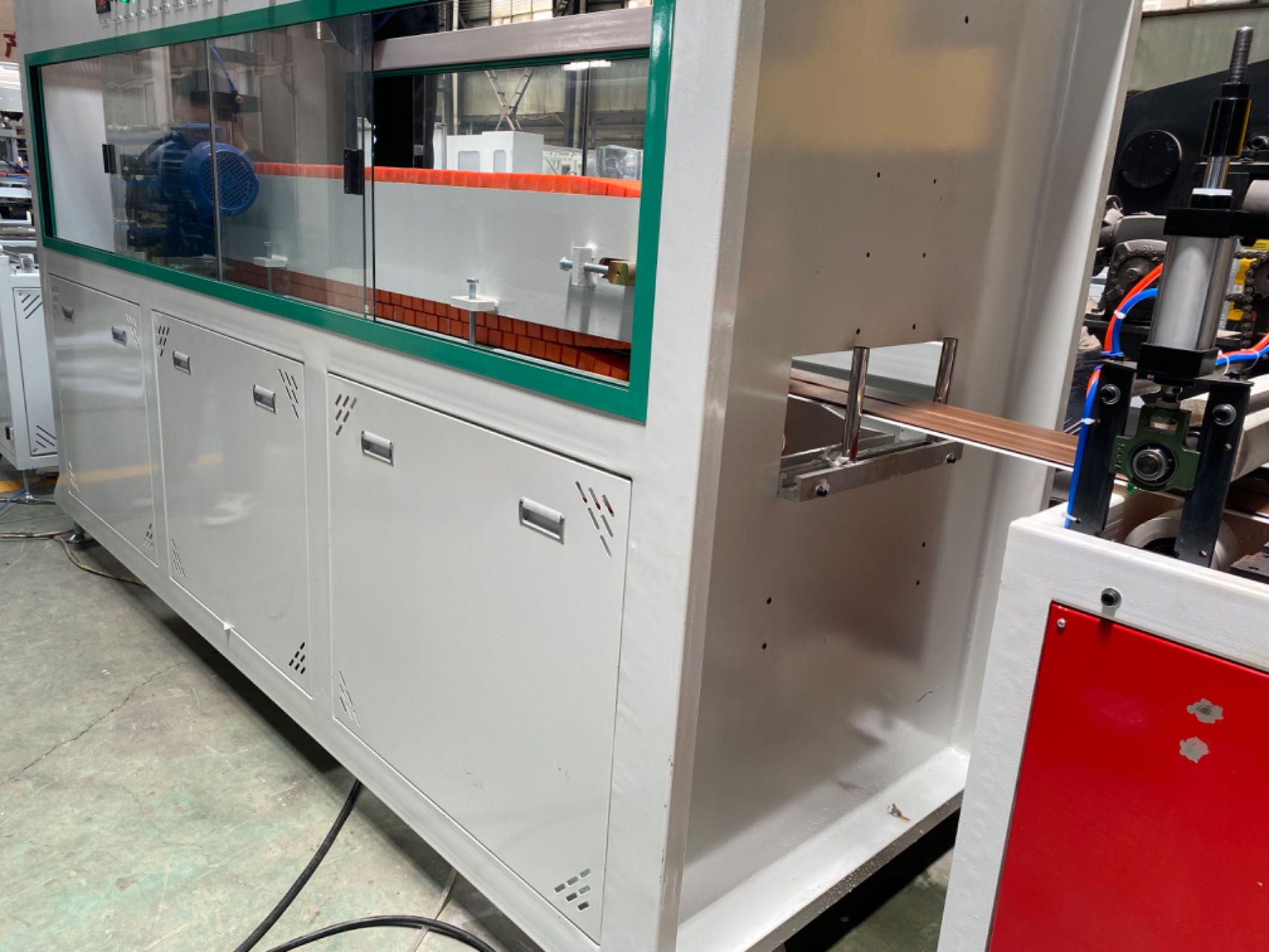

High Output Wood Plastic Profile Extrusion Line

Application

Wood Plastic Composite muchina zvakare yakatumidza huni epurasitiki muchina, wpc muchina, wpc yekugadzira mutsara, wpc extrusion muchina, wpc yekugadzira muchina, wpc chimiro muchina, wpc mbiri yekugadzira mutsara, wpc profile extrusion mutsara zvichingodaro.

Process Flow

PE PP plastiki yehuni:

PE/PP pallets + huni hupfu + zvimwe zvinowedzera (zvinoshandiswa kugadzira zvekunze zvekushongedza zvekuvaka)

Maitiro ekugadzira: Kugaya huni (hupfu, mupunga, goko) —— Musanganisi (purasitiki + hupfu hwehuni) ——Pelletizing muchina——PE PP mapuranga epurasitiki extrusion line

PVC huni plastiki:

PVC poda + huni hupfu + zvimwe zvinowedzera (zvinoshandiswa kugadzira zvemukati zvekushongedza zvekuvaka)

Nzira yekugadzira: Kugaya huni (hupfu, mupunga, goko) ——Musanganisi (purasitiki + hupfu hwehuni) ——PVC yemapuranga epurasitiki extrusion line

Zvakanakira

1. Bhari rinopisa nealuminium casting ring, uye infrared heat uye air-cooling system inotonhorera, uye kutengesa kupisa kunokurumidza uye yunifomu.

2. Zvisungo zvakasiyana zvinogona kusarudzwa maererano nemaitiro akasiyana-siyana kuti uwane yakanakisa plasticization effect.

3. Bhokisi rekutsiva, bhokisi rekugovera rinotora kutakura kwakakosha, chisimbiso chemafuta anotengeswa kunze kwenyika, uye magiya anoshandisa simbi yemhando yepamusoro yealloy, nitriding treatment.

4. Yakakosha dhizaini yegiya bhokisi, bhokisi rekugovera, yakasimbisa iyo inosimudzira kutakura, yakakwirira drive torque, hupenyu hurefu hwebasa.

5. Vacuum molding tafura inotora yakakosha kuwedzera vortex yazvino kutonhora sisitimu, iyo yakanakira kutonhora, uye yakakosha yakatwasuka inodzora yakasarudzika matatu-nzvimbo yekugadzirisa kudzora, zvichiita kuti zvive nyore kushanda zvirinani.

6. Tarakita inotora tekinoroji yekusimudza yakasarudzika, kumusoro uye pasi track back pressure control, basa rakatsetseka, kuvimbika kwakakura, kudhonza kukuru, automatic cutting, uye dust recovery unit.

Details

Conical Twin Screw Extruder

Ne tekinoroji yazvino, kudzikisa simba uye kuve nechokwadi chekugona. Zvinoenderana neyakasiyana mafomula, isu tinopa akasiyana screw dhizaini kuti ive nechokwadi cheplasticizing mhedzisiro uye yakakwirira huwandu. Yakasiyana screws inogona kusarudzwa zvichienderana nekuumbwa kwakasiyana kuti uwane yakanakisa plasticization maitiro.

Mold

Extrusion die head channel iri mushure mekupisa kupisa, girazi polishing uye chroming kuti ive nechokwadi chekuyerera zvakanaka.

Yakakwira-kumhanya kutonhora kuumba kufa inotsigira mutsara wekugadzira nekukurumidza mutsara kumhanya uye nepamusoro kunyatsoshanda;

. High melt homogenity

. Kudzikira kwakaderera kwakavakwa kunyangwe nezvinobuda zvakakwirira

Calibration Table

Calibration tafura inogadziriswa nemberi-kumashure, kuruboshwe-kurudyi, kumusoro-pasi izvo zvinounza kurerutswa uye nyore kushanda;

• Batanidza seti yakazara yevacuum uye pombi yemvura

• Kureba kubva ku4m-11.5m;

• Independent oparesheni panel kuti nyore kushanda

Bvisa muchina

Imwe neimwe claw ine yayo yekudhonza mota, kana imwe traction mota ikamira kushanda, mamwe ma motors anogona kushanda. Inogona kusarudza servo mota kuti ive nehombe yekudhonza simba, yakagadzikana zvakanyanya traction kumhanya uye yakafara siyana yekumhanya yekudhonza.

Imwe neimwe claw ine yayo yekudzora mhepo yekudzora, yakanyatsojeka, kushanda kuri nyore.

Cutter muchina

Saw yekucheka unit inounza nekukurumidza uye yakagadzikana yekucheka ine yakatsetseka incision. Isu tinopawo kutakura uye kucheka kwakabatanidzwa unit inova yakanyanya compact uye ine mari dhizaini.

Tracking cutter kana kusimudza saw cutter inotora kaviri chiteshi guruva yekuunganidza system; synchronous kutyaira nemhepo silinda kana servo mota control.

Technical Data

| Model | SJZ51 | SJZ55 | SJZ65 | SJZ80 |

| Extruder model | Ф51/105 | Ф55/110 | Ф65/132 | Ф80/156 |

| Main moror simba (kw) | 18 | 22 | 37 | 55 |

| Kugona(kg) | 80-100 | 100-150 | 180-300 | 160-250 |

| Upamhi hwekugadzira | 150mm | 300mm | 400mm | 700mm |