High Speed Yakakwirira Inoshanda PE Pipe Extrusion Line

Tsanangudzo

Hdpe pombi muchina unonyanya kushandiswa kugadzira pombi dzekudiridza dzekurima, pombi dzemvura, pombi dzegasi, pombi dzinopa mvura, pombi dzetambo dzekombi nezvimwe.

PE pombi extrusion line ine pombi extruder, pombi inofa, calibration mauniti, tangi yekutonhodza, kudhonza-kubvisa, cutter, stacker/coiler uye zvese zvinotenderedza. Hdpe pombi kugadzira muchina inogadzira mapaipi ane dhayamita kubva pa20 kusvika 1600mm.

Iyo pombi ine zvimwe zvakanakisa senge kudziyisa kusagadzikana, kuchembera kusimba, kusimba kwemagetsi, kutsemuka kusagadzikana kwemamiriro ekunze, kunaka kunoramba kusimuka, etc. Hdpe pombi extrusion muchina wakagadzirwa nehupamhi hwepamusoro extruder uye wakashongedzerwa nereducer inomhanya zvakanyanya uye yakaderera ruzha, gravimetric dosing unit uye ultrasonic ukobvu chiratidzo chinogona kuunganidzwa zvinoenderana nezvinodiwa nemutengi kuti akwire pombi.

Turn key solution inogona kupihwa, senge laser printer crusher, shredder, water chiller, air compressor etc. kuti uwane yakakwirira-giredhi uye otomatiki chubhu kugadzirwa.

Process Flow

Raw material+ Master Batches → Kusanganisa → Vacuum Feeder → Plastic Hopper Drier → Single screw extruder → Co-extruder yeruvara tambo & Multi Layers → Mold uye calibrator→ Vacuum Calibration Tangi → Pyaya Mvura Inotonhorera Tangi → Muchina wekubvisa → Mushini wekucheka → Sita (Winding machine)

Zvinhu uye Zvakanakira

1.Hdpe pombi muchina inogadzirwa nesu zvichibva kuEuropean advanced tekinoroji uye R&D ruzivo rwemapurasitiki emuchina kwemakore mazhinji, dhizaini yepamusoro, chimiro chinonzwisisika, kuvimbika kwepamusoro, dhigirii yepamusoro otomatiki.

2. Hdpe pombi extruder ine yakakosha dhiramu yekudyisa chimiro inogona kunyanya kuvandudza extrusion kugona.

3. Kunyatsodzikama kuzvidzora, kunaka kwepurasitiki, kushanda kwakagadzikana.

4. Hdpe pipe muchina inotora PLC control system, ichiziva kuwiriranisa uye otomatiki.

5. Human-computer interface iri nyore kushanda, yakanakira uye yakavimbika.

6. Spiral nelattice basket type inofa kufa nekuda kwesarudzo.

7. Kuchinja zvimwe zvikamu zvemutsara zvinogona zvakare kuona maviri-layer uye akawanda-layer co-extrusion.

8. Kuchinja zvimwe zvikamu zvemutsara zvinogonawo kubudisa PP, PPR mapaipi.

Details

Single Screw Extruder

Zvichienderana ne33: 1 L/D reshiyo yekugadzira screw, isu takagadzira 38:1 L/D reshiyo. Kuenzaniswa ne33: 1 reshiyo, 38: 1 chiyero ine mukana we100% plasticization, wedzera kubuda kwehuwandu ne30%, kuderedza kushandiswa kwemagetsi kusvika ku30% uye kusvika kunenge mutsara extrusion performance.

Simens Bata Screen uye PLC

Nyorera chirongwa chakagadziridzwa nekambani yedu, iva neChirungu kana mimwe mitauro kuti uise muhurongwa.

Spiral Chimiro cheBharel

Kudyisa chikamu chedhiramu shandisa spiral chimiro, kuve nechokwadi chekudya chenyama chakagadzikana uye zvakare kuwedzera simba rekudyisa.

Special Design of Screw

Screw yakagadzirwa neyakakosha chimiro, kuve nechokwadi chepurasitiki yakanaka uye kusanganisa. Zvinhu zvisina kunyungudutswa hazvigone kupfuura ichi chikamu che screw.

Mhepo Yakatonhodzwa Ceramic Heater

Ceramic heater inovimbisa hupenyu hurefu hwekushanda. Iyi dhizaini ndeyekuwedzera nzvimbo iyo hita inosangana nemhepo. Kuve nemhepo inotonhorera inotonhorera.

High Quality Gearbox

Kurongeka kwegiya kuve nechokwadi 5-6 giredhi uye yakaderera ruzha pazasi 75dB. Compact chimiro asi ine yakakwirira torque.

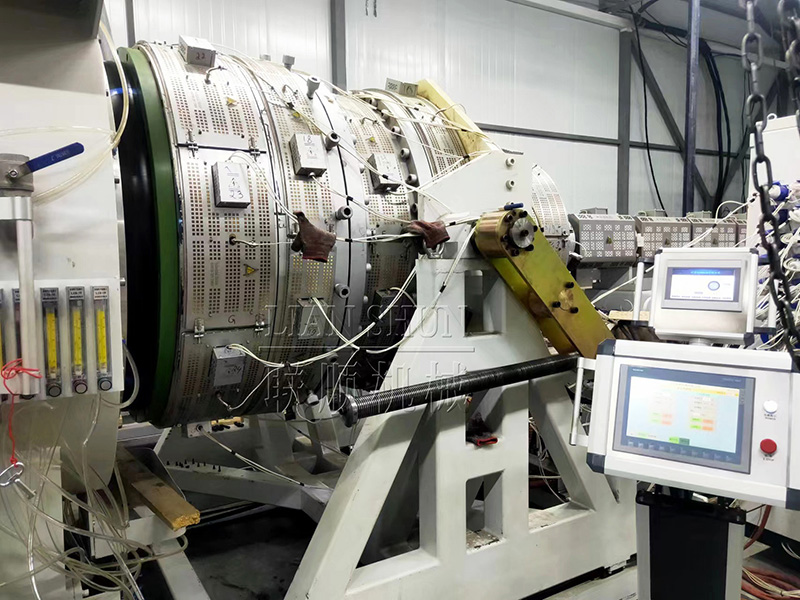

Extrusion Die Head

Extrusion kufa musoro shandisa spiral chimiro, yega yega zvinhu inoyerera chiteshi inoiswa zvakaenzana. Imwe neimwe chiteshi mushure mekupisa kupisa uye girazi polishing kuti ive nechokwadi chekuyerera zvakanaka. Kufa musoro chimiro compact uye zvakare inopa yakagadzikana kudzvanywa, nguva dzose kubva 19 kusvika 20Mpa. Pasi pekumanikidza uku, hunyoro hwepombi hwakanaka uye hushoma hunoita pakubuda kwesimba. Inogona kugadzira imwe layer kana yakawanda-layer pombi.

Kufambisa Chishandiso cheDie Head

Kune yakakura saizi inofa musoro, inofamba chishandiso inogona kufambisa musoro wekufa kumberi uye kumashure, zvakare gadzirisa kureba kwemusoro wekufa. Kushanda kunokurumidza uye nyore.

Die Head Rotary Device

Kune yakakura saizi inofa musoro ine inotenderera mudziyo, kufa musoro unogona kutenderera ne90 degree. Kana uchichinja gwenzi, mandrel, kufa musoro kuchachinja 90 degree. Inogona kushandisa crane kusimudza uye kuchinja gwenzi uye mandrel. Iyi nzira iri nyore kwazvo.

Heat Exhausting Device

Mudziyo uyu unowedzerwa pamusoro wekufa kuti ubudise pombi hombe uye gobvu. Kupedza kupisa mukati mepombi uye pombi inotonhorera mukati memadziro. Iyo inopisa yakapera inogona kushandiswa kuomesa mbishi.

Chishandiso chekutonhodza cheCore

Kana tichigadzira pombi ine dhayamita hombe uye kukora kwemadziro, isu tichashandisa mvura inotonhorera kana mafuta pamwe chete neinotonhodza feni kutonhodza musimboti wemusoro wekufa kudzivirira kupisa uye kuve nechokwadi chemhando yakanaka yezvinhu.

Vacuum Calibration Tangi

Vacuum Calibration tangi inoshandiswa kugadzira uye kutonhora pombi, kuitira kuti isvike pachiyero chepombi saizi. Isu tinoshandisa kaviri-chamber chimiro. Kamuri yekutanga iri muhurefu hupfupi, kuve nechokwadi chekutonhora kwakasimba uye vacuum basa. Sezvo calibrator inoiswa pamberi pekamuri yekutanga uye pombi chimiro chinoumbwa zvakanyanya necalibrator, dhizaini iyi inogona kuita kuti kukurumidza uye zvirinani kuumbwa uye kutonhora kwepombi.

Kutonhodza Kwakasimba kweCalibrator

Iine yakakosha kutonhora sisitimu ye calibrator, iyo inogona kuve nani kutonhora mhedzisiro yepombi uye kuve nechokwadi chekumhanya. Zvakare nemhando yakanaka yekupfapfaidza nozzle kuti ive nani kutonhora mhedzisiro uye isiri nyore kuvharika netsvina.

Zvirinani Tsigiro yePipe

Kune hombe saizi pombi, saizi yega yega ine yayo semicircular yekutsigira ndiro. Ichi chimiro chinogona kuchengetedza pombi kutenderera zvakanaka.

Silencer

Isu tinoisa silencer pane vacuum gadzirisa vharafu kuderedza ruzha kana mweya wauya muvacuum tank.

Pressure Relief Valve

Kuchengetedza tangi yevacuum. Kana vacuum degree yasvika pakugumira, vharuvhu inovhurika otomatiki kudzikisa vacuum degree kudzivirira kutyoka kwetangi. Vacuum degree kugumira kunogona kugadziriswa.

Kaviri Loop Pipeline

Imwe neimwe loop ine mvura yekusefa system, kupa yakachena inotonhorera mvura mukati metangi. Kaviri loop zvakare inovimbisa kuenderera mberi kwekupa mvura inotonhorera mukati metangi.

Mvura, Gasi Separator

Kuparadzanisa gasi mvura mvura. Gasi rakapera kubva kumusoro. Mvura inoyerera ichipinda muzasi.

Full Automatic Water Control

Ne mechanical tembiricha kutonga kuti ive yakarurama uye yakagadzikana kudzora tembiricha yemvura.

Yese mvura inlet uye yekubuda system inodzorwa yakazara otomatiki, yakagadzikana uye yakavimbika.

Centralized Drainage Device

Yese madhiraini emvura kubva muvacuum tank akabatanidzwa uye akabatanidzwa mune imwe pombi isina tsvina. Ingobatanidza pombi yakabatanidzwa kune kunze kwemvura, kuita kuti kushanda kuve nyore uye nekukurumidza.

Pfayira Tangi Yemvura Inotonhorera

Kutonhodza tangi rinoshandiswa kutonhora pombi mberi.

Pipe Clamping Chishandiso

Ichi chishandiso chinogona kugadzirisa kutenderera kwepombi kana pombi ichibuda kubva mutangi rekutsvaira.

Mvura Tangi Sefa

Nesefa mutangi remvura, kudzivirira chero tsvina yakakura kana mvura yekunze ichipinda.

Quality Spray Nozzle

Yemhando yekupfapfaidza nozzles ine zvirinani kutonhora mhedzisiro uye isiri nyore kuvharika netsvina.

Pipe Inotsigira Kugadzirisa Chishandiso

Tsigira nekugadzirisa basa kutsigira pombi ine dhayamita dzakasiyana.

Pipe Support Device

Kunyanya kushandiswa pakugadzira pombi ine dhayamita hombe uye kukora kwemadziro. Chishandiso ichi chinopa humwe tsigiro kumapombi anorema.

Haul Off muchina

Haul off muchina inopa yakakwana yekudhonza simba kudhonza pombi zvakadzikama. Zvinoenderana nehukuru hwakasiyana hwepombi uye ukobvu, kambani yedu inogadzirisa kumhanya kwekufambisa, nhamba yezvinzwa, uye inobudirira yekudhonza kureba. Kuve nechokwadi chemutambo wepombi extrusion kumhanya uye kumhanya kwekugadzira, dzivirirawo deformation yepombi panguva yekudhonza.

Kuparadzanisa Traction Motor

Imwe neimwe claw ine yayo yekudhonza mota, kana imwe traction mota ikamira kushanda, mamwe mamotor anogona achiri kushanda. Inogona kusarudza servo mota kuti ive nehombe yekudhonza simba, yakagadzikana zvakanyanya traction kumhanya uye yakafara siyana yekumhanya yekudhonza.

Claw Kugadzirisa Chishandiso

Zvidyarwa zvese zvakabatanidzwa kune mumwe nemumwe, kana kugadzirisa nzvimbo yezvipikiri kudhonza pombi muhukuru hwakasiyana, makuhwa ese achafamba pamwechete. Izvi zvichaita kuti kushanda nekukurumidza uye nyore.

Mushandisi Hushamwari Dhizaini

NeSiemens hard ware uye mushandisi ane hushamwari software yakagadzirwa nekambani yedu. Iva neyakawiriraniswa basa neextruder, ita kuti kushanda kuve nyore uye nekukurumidza. Zvakare mutengi anogona kusarudza chete mamwe machira ekushanda kudhonza mapombi madiki.

Separate Air Pressure Control

Imwe neimwe claw ine yayo yekudzora mhepo yekudzora, yakanyatsojeka, kushanda kuri nyore.

. High kudhonza simba pasina kurasikirwa chimiro mapaipi

. Yakashongedzerwa ne 2, 3, 4, 6, 8, 10 kana 12 makonye maererano nekushandiswa

. Servo mota kutyaira yekupa yakagadzikana torque uye kumhanya

. Motorized positioning yemakonye ezasi

. Kushanda kuri nyore

. Dziviriro yakavharwa zvachose kuitira kuchengetedza kwakanyanya

. Chain conveyors ane special rabha pads pamaketani ayo asina chiratidzo papombi.

. Kuwiriranisa neiyo extruder screw kumhanya inobvumira yakagadzikana kugadzirwa panguva yekuchinja kukurumidza kwekugadzira

Muchina wekucheka pombi

Purasitiki pombi yekucheka inonziwo pombi yekucheka muchina unodzorwa neSiemens PLC, uchishanda pamwe chete nekubvisa unit kuti uve nekucheka chaiko. Mutengi anogona kuseta hurefu hwepombi yavanoda kucheka. Multi-feed-in zviito zvekuzadzikiswa kweimwe nzira yekucheka (chengetedza mashizha nemasaha, kudzivirira kubva kune blade uye masaha akanamatira kune gobvu pombi uye kuchekwa kwepombi kwakatsetseka).

Universal Clamping Chishandiso

Isa universal clamping mudziyo kune akasiyana pombi saizi, hapana chikonzero chekuchinja clamping mudziyo kana pombi yachinja.

Saw uye Blade Inochinjika

Vamwe vanocheka vakashongedzerwa nesese uye blade. Saw uye blade kucheka zvinochinjika kune akasiyana pombi saizi. Zvakare, saha uye blade zvinogona kushanda pamwechete kune zvakakosha zvinodiwa.

Central Height Adjustment

Nemagetsi ekugadzirisa mudziyo we clamping mudziyo. Operation nekukurumidza uye nyore. Ne muganhu chinja kuti uve nechokwadi chekuchengeteka.

. Otomatiki synchronization pamwe extrusion kumhanya

. Planetary yakashongedzerwa dhisiki uye milling cutter yekucheka uye chamfering

. Chip-yemahara yakashongedzerwa nedhisiki blade kuti ive nechokwadi chekucheka chakatsetseka pasina guruva

. Bata screen control panel

. Mafambiro ese ane mota uye anodzorwa ne control panel

. Kuvharira pombi nekushandisa universal clamping kuti ishande nyore

. Zvido zvishoma zvekuchengetedza

. Yakavharwa zvachose uye yakachengetedzwa muchina kuitira kuchengetedza kwakanyanya

Stacker

Kutsigira nekuburutsa mapaipi. Hurefu hwe stacker hunogona kugadzirwa.

Kudzivirira kwepombi

Ne roller, kuchengetedza pombi pamusoro paunenge uchifambisa pombi.

Central Height Adjustment

With nyore kugadzirisa mudziyo kugadzirisa nechepakati kureba kune akasiyana pombi saizi.

Coiler

Kukoira pombi kuita roller, zviri nyore kuchengetedza uye kutakura. Inowanzoshandiswa pombi pazasi saizi 110mm. Iva nechiteshi chimwe chete uye kaviri chiteshi chesarudzo.

Kushandiswa kwe servo mota

Inogona kusarudza servo mota yekutamisa pombi uye mhepo, yakanyatsojeka uye iri nani pombi kutamiswa.

Technical Data

| Diameter range(mm) | Extruder model | Max. Kugona (kg/h) | Max. kumhanya kwemutsara (m/min) | Extruder power (KW) |

| Ф20-63 | SJ65/33 | 220 | 12 | 55 |

| Ф20-63 | SJ60/38 | 460 | 30 | 110 |

| Ф20-63 Dual | SJ60/38 | 460 | 15 × 2 | 110 |

| Ф20-110 | SJ65/33 | 220 | 12 | 55 |

| Ф20-110 | SJ60/38 | 460 | 30 | 110 |

| Ф20-160 | SJ60/38 | 460 | 15 | 110 |

| Ф50-250 | SJ75/38 | 600 | 12 | 160 |

| Ф110-450 | SJ90/38 | 850 | 8 | 250 |

| Ф250-630 | SJ90/38 | 1,050 | 4 | 280 |

| Ф500-800 | SJ120/38 | 1,300 | 2 | 315 |

| Ф710-1200 | SJ120/38 | 1,450 | 1 | 355 |

| Ф1000-1600 | SJ 90/38 SJ 90/38 | 1,900 | 0.6 | 280 280 |